Introduction

In the current context of global momentum in favour of renewable electricity catalysed by spectacular levelized production cost decrease, higher storage capacity is required to ensure security and flexibility providing a portfolio of services from grid services to the decarbonization of energy intensive sectors like the transport, industry or heating and cooling sector.

Current viable business cases for energy storage consider mainly low energy-to-power ratio storage applications. In that case, battery systems reveal to be decisive components of the energy management system especially for fast response services and short-term grid storage. Nevertheless, in our new energy paradigm where distributed renewable generation cohabits with increasingly larger wind or PV power plants located farther away from consumption sites, the ability to store seasonably large quantities of energy in the form of a dispatchable energy carrier is a key element.

For that purpose, hydrogen produced from electrolysis reveals to be a key pathway to unlock the full potential of renewable and especially for seasonal energy storage of large energy quantities and more specifically for all situations dealing with a large energy-to-power ratio situation. Hydrogen having a low volumetric energy density, requires to be either compressed to high pressure, liquefied or combined with other elements acting as hydrogen carriers. Amongst all possibilities, ammonia is a carbon-free and dispatchable energy carrier allowing to store large quantities of renewable electricity. It is a primary candidate to allow a secure and clean supply of renewable energy for various stationary or mobile applications and with ability to provide a wide range of energy storage services using existing infrastructures and both well-defined regulation and acceptable safety history for over 75 years. However, technical challenges remain to be overcome in order to ensure a flexible and cost competitive production of ammonia from intermittent renewable electricity sources. In addition to that, efficient energy discharge processes from NH3 must be developed in order to best leverage the clean energy produced upstream by the renewable asset.

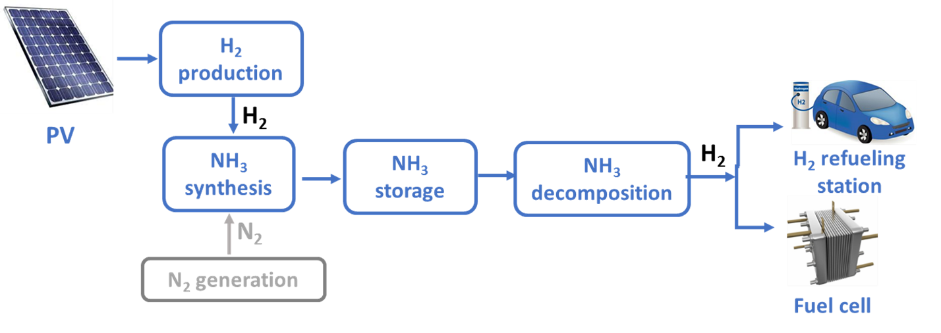

The ARENHA project aims at using ammonia as a green hydrogen carrier and for that purpose it develops its main activities around the green hydrogen production, ammonia synthesis, ammonia storage and ammonia dehydrogenation (Figure 1). Innovative materials are developed and integrated into ground-breaking systems in order to demonstrate a flexible and profitable power-to-ammonia value chain but also several key energy discharge processes. Specifically, ARENHA is developing advanced SOEC for renewable hydrogen production, catalysts for low temperature/pressure ammonia synthesis, solid absorbents for ammonia synthesis intensification and storage, catalysts and membrane reactors for ammonia decomposition for pure hydrogen (>99.99%) production. Energy discharge processes studied in ARENHA tackle various applications from ammonia decomposition into pure H2 for FCEV, direct ammonia utilization on SOFCs for power and ICEs for mobility.

ARENHA will demonstrate the full power-to-ammonia-to-usage value chain at TRL 5 and the outstanding potential of green ammonia to address the issue of large-scale energy storage through LCA, sociological survey, techno-economic analysis deeply connected with multiscale modelling.