Objectives and Work plan

Objectives

ARENHA will demonstrate the full power-to-ammonia-to-usage value chain at TRL 5 and the outstanding potential of green ammonia to address the issue of large-scale energy storage through LCA, sociological survey, techno-economic analysis deeply connected with multiscale modelling. For this purpose, breakthrough technologies will be developed and integrated along the overall value chain. The main technical objectives on material and system level are the following:

- to develop and integrate innovative solid oxide cell materials into a flexible high temperature electrolysis demonstration unit producing 1.5 Nm3/hr hydrogen at ambient pressure to be connected on a real PV plant.

- to develop and integrate innovative materials into a synthesis loop enabling to operate a flexible Haber Bosch production unit of 10 kgNH3/day at lower pressure (<50 bar) and temperature (<450 °C).

- to develop and integrate innovative materials into a decomposition reactor able to generate 10 Nm3/hr of pure hydrogen (>99.99%) from green ammonia.

- to develop and test innovative materials and solutions for the alternative direct synthesis and utilization of next-generation green ammonia.

- to demonstrate ammonia as a flexible energy carrier through the development of a fully integrated prototype for green ammonia synthesis and decomposition.

- to assess the social acceptance, techno-economic-environmental feasibility, and replication potential of the developed value chains.

Work plan

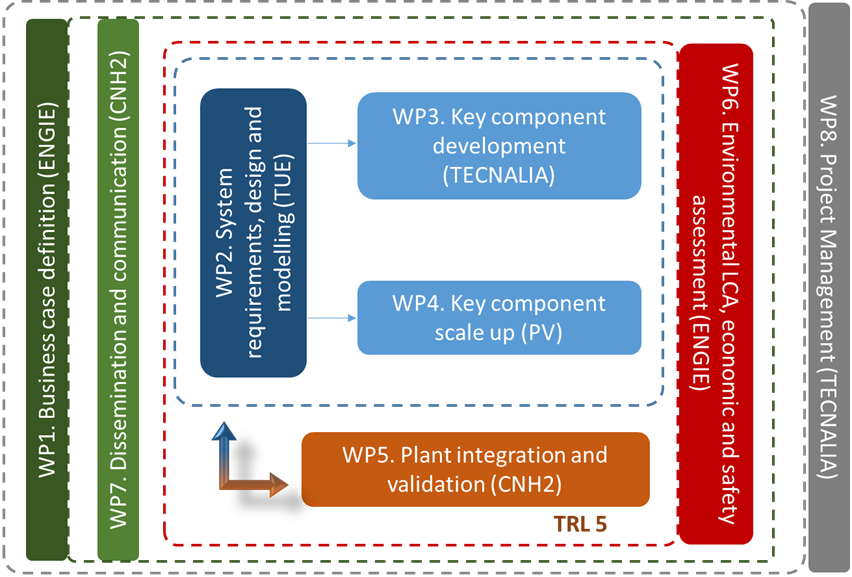

The project scheduled work plan comprises activities related to the whole value chain and it will be implemented in 48 months. It is broken down in eight work packages following the focus on using ammonia as green hydrogen carrier and for that purpose it develops its main activities around green hydrogen production, ammonia synthesis, ammonia storage and ammonia dehydrogenation. Finally, the novel materials and systems will be integrated into a testing infrastructure combined with an ammonia storage tank for proof of concept and validation to demonstrate the full power-to-ammonia-to usage value chain at TRL 5.

WP1: Business case definition

WP1 aims for an early business case definition, clear understanding of market barriers and needs, regulatory framework and potential risks.

The final objective is to guide the project towards highly deployable results, fulfilling the needs of the target market. WP1 also sets the framework for high impact exploitation actions to promote and support future market uptake. WP1 starts in month 1 and goes through the whole project.

WP2: System requirements, design and modelling

WP2 translates the general framework established in WP1 into a set of specifications for the novel ARENHA energy storage value chain that will be demonstrated. These specifications must be in accordance with every business model defined in WP1 and will gather the inputs from the end-users. In addition, WP2 will gather all the modelling related to each technology and complete system design.

WP3: Key component development

WP3 is the technical work package where the key materials and components of ARENHA will further optimised and tested before the final scale-up at TRL 5.

This work package runs for the first 24 months on the project and includes the following actions:

- New cell materials for optimized SOEC stacks for hydrogen production

- Materials for ammonia synthesis

- Materials for solid-state ammonia storage

- Membranes and membrane reactors for ammonia decomposition

- Materials and systems for power generation from green ammonia

WP4: Key component scale-up

In WP4 the optimise key materials and components from WP3 will be scale-up to TRL5 and the different main components for the ammonia-based energy system pre-product pilot plant will design, build and commissioned. The pilot plant will be delivered to and tested in CNH2 facilities in WP5

This work packages includes the following pilot prototypes:

- SOEC stack modules and balance of plant components (BoP) of electrolyser system for hydrogen production

- Ammonia synthesis system prototype based on Haber Bosch with an advanced absorber.

- Ammonia decomposition membrane reactor prototype

WP5: Plant integration and validation

WP5 will provide the proof-of-concept in relevant industrial environment (TRL 5). The main components (electrolyser, ammonia production system, membrane reactor and ammonia storage) will be integrated and tested at CNH2 for demonstration of the whole ammonia-based energy storage system.

WP6: Environmental LCA, economic and safety assessment

In WP6, LCA, LCC, LCS and techno-economic assessment will be performed, in order to prove the viability of the developed materials and technologies, and to give insights about the further use of the technologies. The results of WP5 and WP6 will directly feed into the definition of business cases in WP1, dissemination activities.

WP7: Dissemination and communication

WP7 runs throughout the whole project, feeding from the results of previous work packages, and providing support to exploitation of project results through highly focused communication and dissemination activities.

WP8: Project Management

WP8 ensures an effective project management all along the execution of the work plan which includes the following actions:

- Overall administrative, contractual and financial reporting

- Organization of project meetings

- Coordination of internal communication

- Risk planning